What is the Flowsheet Copilot?

Copilot is an AI-supported application developed by Simulate 365 to create and optimize DWSIM flowsheets. Copilot allows to navigate through a generated solution space for your simulation by defining an objective function for multi-criteria optimization and to download the 5 best flowsheet for validation and fine-tuning.

Who can benefit from ?

Copilot can be useful for a wide range of users, including:

- Researchers who want to evaluate new separation processes.

- Engineers who are designing new processes including separation section or plan to improve existing ones, and need to identify the optimal design.

- Operations managers who want to improve efficiency and reduce costs by identifying the most cost and product efficient design.

- Anyone who wants to avoid the trial and error associated with flowsheet simulation.

Getting Started with Flowsheet Copilot:

- Prerequisites

You need a DWSIM flowsheet that contains the components you want to separate. - Simulate 365 account

Copilot is a web-based application on our Simulate 365 Dashboard.

To access Dashboard, sign up via https://simulate365.com/registration/, activate your account and access Dashboard on https://dashboard.simulate365.com/. - Copilot Access

Login to Simulate 365 to get your license in the shop. You can get a 2-week free trial to try Copilot.

Tutorial

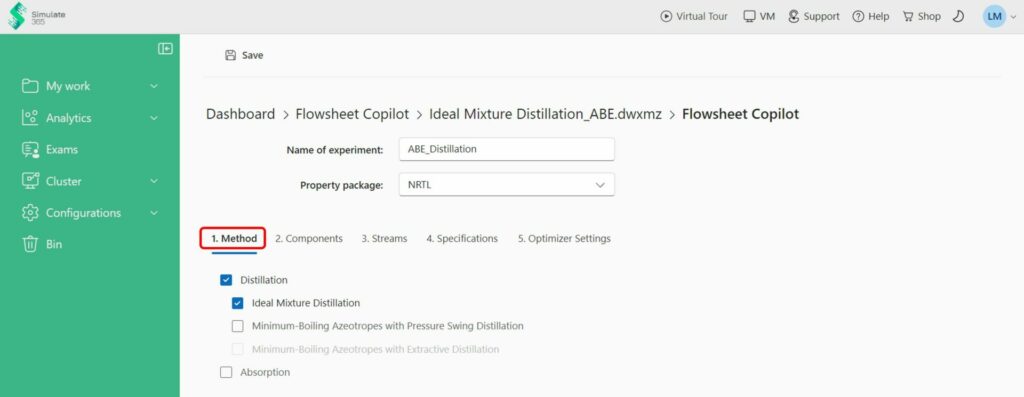

The Flowsheet Copilot can create separation sections for Ideal Mixture Distillation, Minimum-boiling azeotropic distillation using Pressure Swing Distillation or Extractive Distillation, and simple Absorption.

Tutorial – Distillation

Ideal Mixture Distillation

We use the simple three-component separation of an Acetone-Butanol-Ethanol mixture to demonstrate how Flowsheet Copilot generates flowsheets.

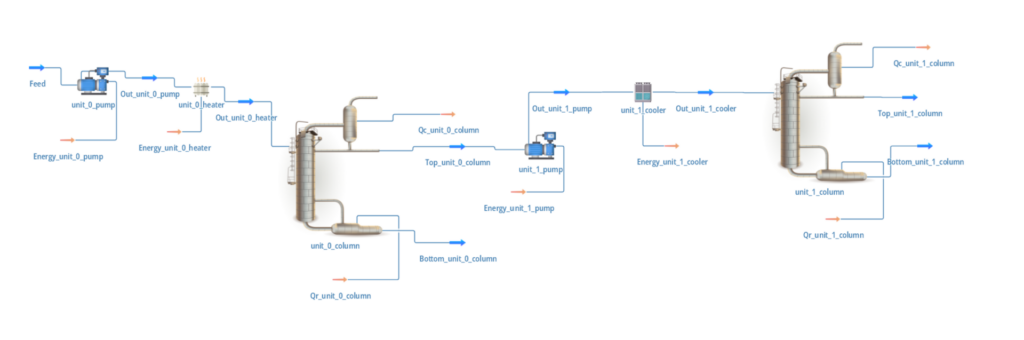

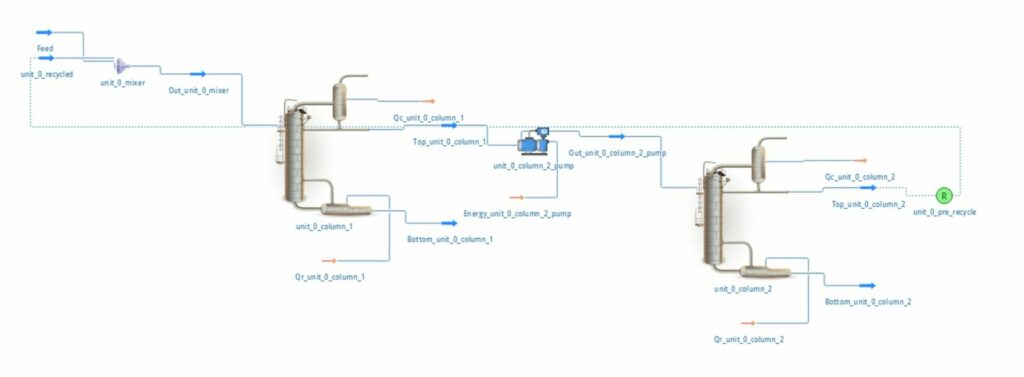

In a multicomponent distillation process, multiple distillation columns are used to separate all components. The sequence in which these columns are arranged is known as column sequencing. Copilot generates flowsheets for all sequences:

Sequence 1:

Sequence 2:

Step 1: Upload the DWSIM flowsheet

Upload an (empty) DWSIM flowsheet containing your separation components to Simulate 365 Dashboard and let it analyze.

Step 2: Create your Experiment

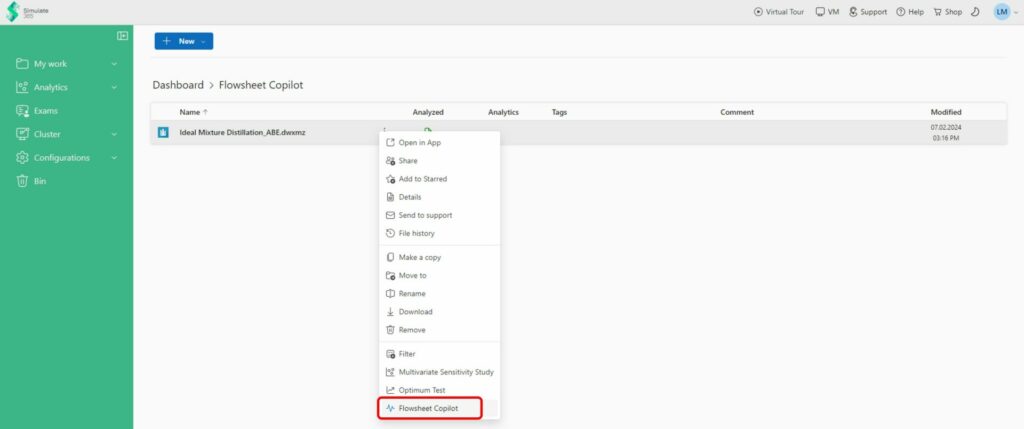

a) Right-click on your flowsheet and access “Flowsheet Copilot”.

b) Create a “New Experiment” and define a name and the property package and select the separation method.

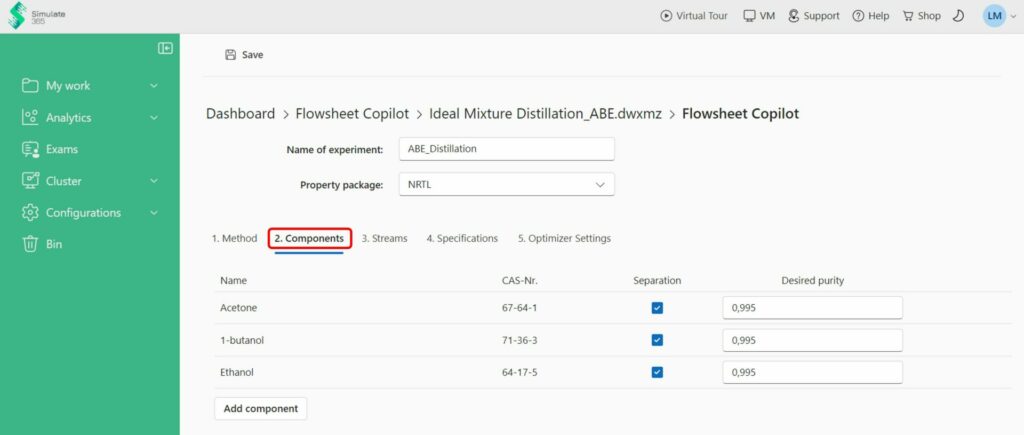

c) Select the components you want to separate and the desired purity for each of their respective outlet streams. You can also add components from the DWSIM database to be used for the simulation. Each component tagged with “Separation” will be separated in a separate product stream.

d) Define your feed stream properties.

e) Define ranges for your unit operation specifications. For the Ideal Distillation method, you can vary the number of stages and feed stage (together defined using the number of stages from feed to top and bottom to feed), the top/condenser pressure, reflux ratio and bottom product flow rate as specifications and heater temperatures that pre-heat your streams before entering the distillation columns.

f) (Optional) Define the convergence timeout and internal and external tolerances for your flowsheet. These features can be used to influence the convergence of complicated or large flowsheets. You can also define maximum process costs that will be considered in the optimization.

g) Save the experiment.

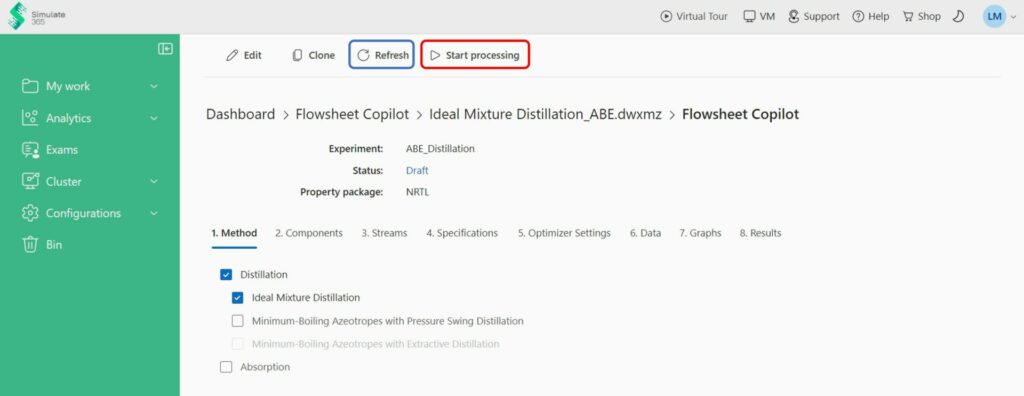

Step 3: Run the optimization

Start the flowsheet generation and optimization from your Dashboard, after saving the experiment. You can refresh the page from time to time, to view first results and see your experiment progress.

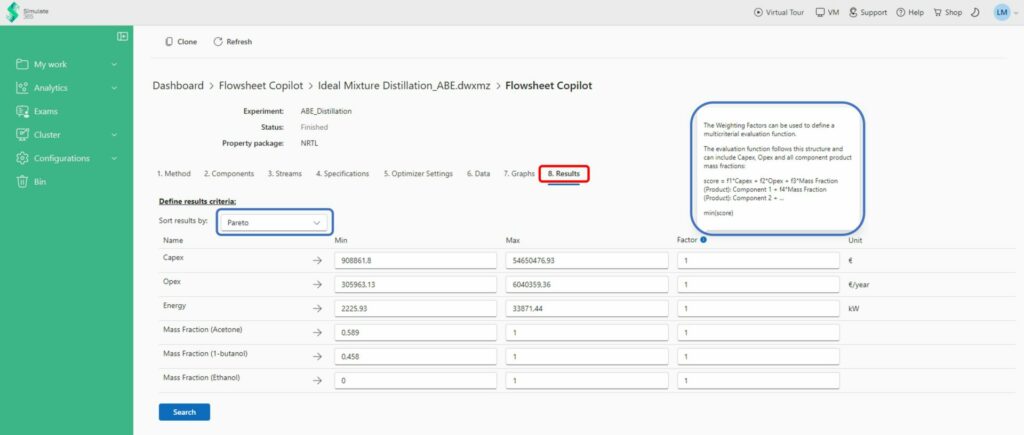

Step 4: Navigate through the solution space

a) After your calculation is finished, you can view results for all generated, converged or non-converged, flowsheets in the Data tab. For each generated flowsheet, you can view the defined unit operation specifications (inputs) and total energy consumption, Capex and Opex costs, as well as product purities for each component (outputs).

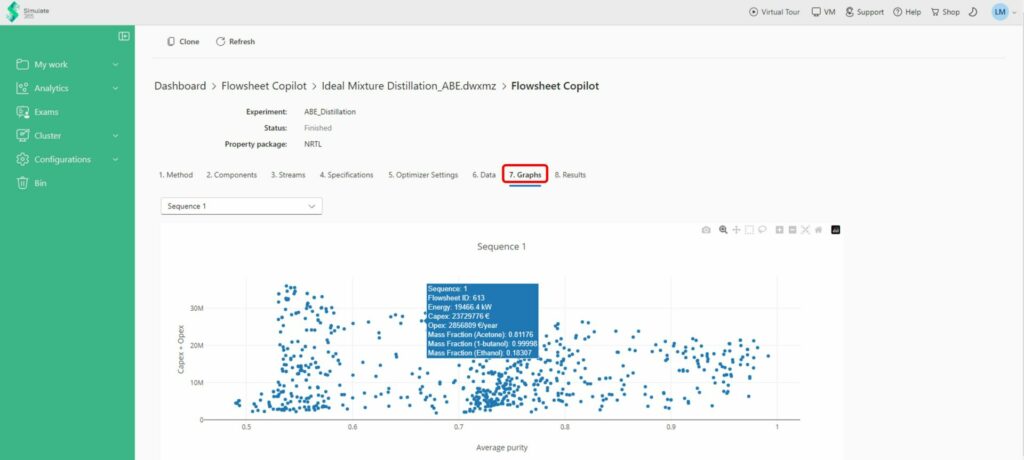

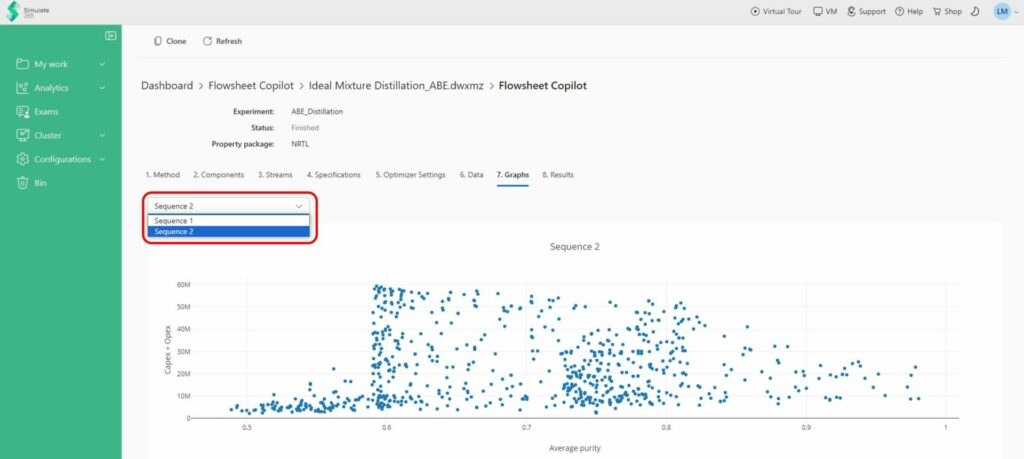

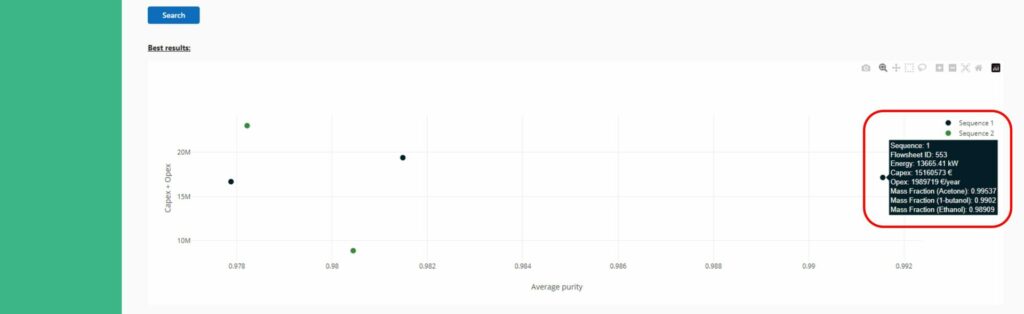

b) In the Graphs tab, you can navigate through all calculated solutions and inspect interesting areas by zooming in.

The graphs are created for each generated sequence.

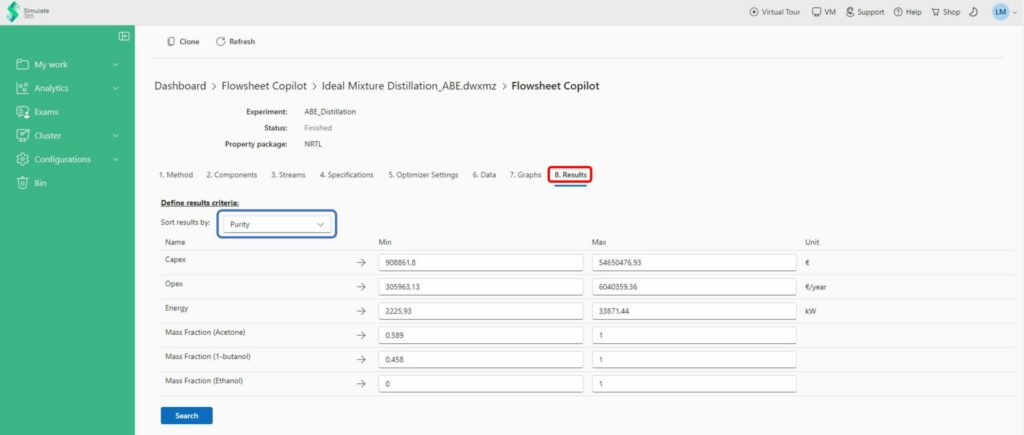

c) You can also investigate your solution space by defining search criteria among all calculated flowsheets and sort the results by best purity…

…or pareto-optimal solution based on your objective function.

d) Download your best flowsheet(s) by selecting them from the resulting plot

Minimum-boiling azeotropes with Pressure Swing Distillation

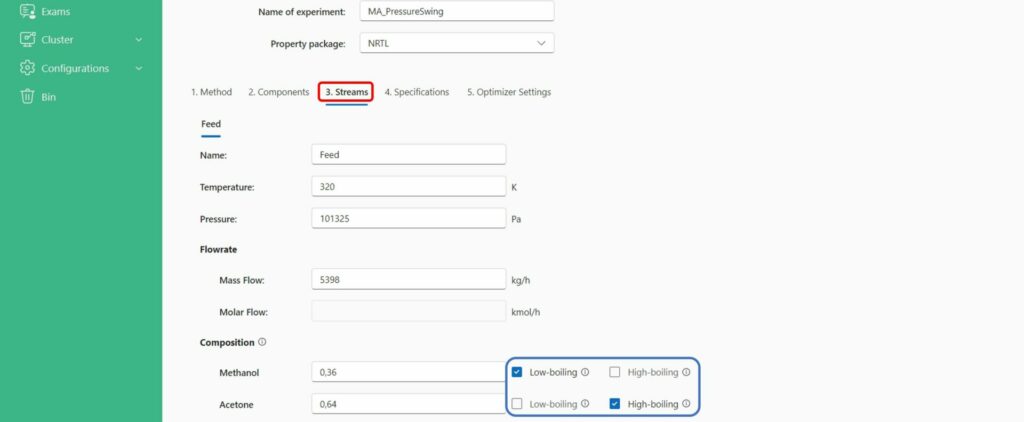

Pressure Swing Distillation (PSD) is used to separate two-component non-ideal mixtures with pressure-sensitive azeotropes using two distillation columns which are operated in sequence at two different pressures.

The experiment follows the same strategy as for Ideal Distillation with small differences in the set-up:

1.Components: You can only use two components for the simulation

2. Streams:

You define which component is the low-boiling or and high-boiling component at the defined pressure in the first column. The high-boiling component is expected to be the main bottom product of the first column.

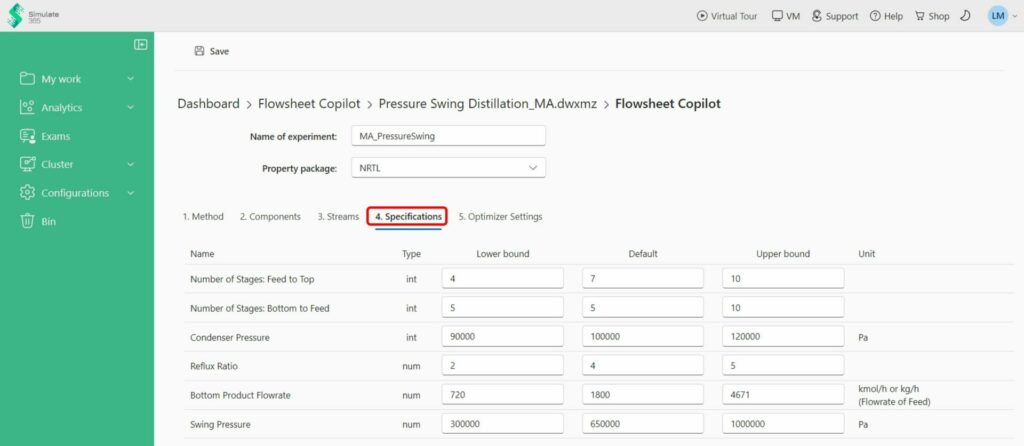

3. Specifications:

You can vary the number of stages and feed stage (together defined using the number of stages from feed to top and bottom to feed), the top/condenser pressure, reflux ratio and bottom product flow rate as specifications and the swing pressure, meaning the expected pressure for the second column.

Minimum-boiling azeotropes with Extractive Distillation

Currently under review

Tutorial – Absorption

Simple Absorption

Copilot can also generate and optimize flowsheets for gas-liquid absorption where a specific gas from the gas mixture is separated by using an appropriate solvent.

The experiment follows the same strategy as for Ideal Distillation with small differences in the set-up:

1. Components: You can select the components to be separated, similarly to distillation, as well as one component that serves as solvent. Instead of product purities, you define the mass recovery of each separation component in the outlet gas stream.

2. Streams:

You define two inlet streams: The gas feed stream, similarly as in Distillation, and the pure solvent stream.

3. Specifications:

You can vary the number of stages, column top pressure, solvent temperature and solvent flowrate as specifications.