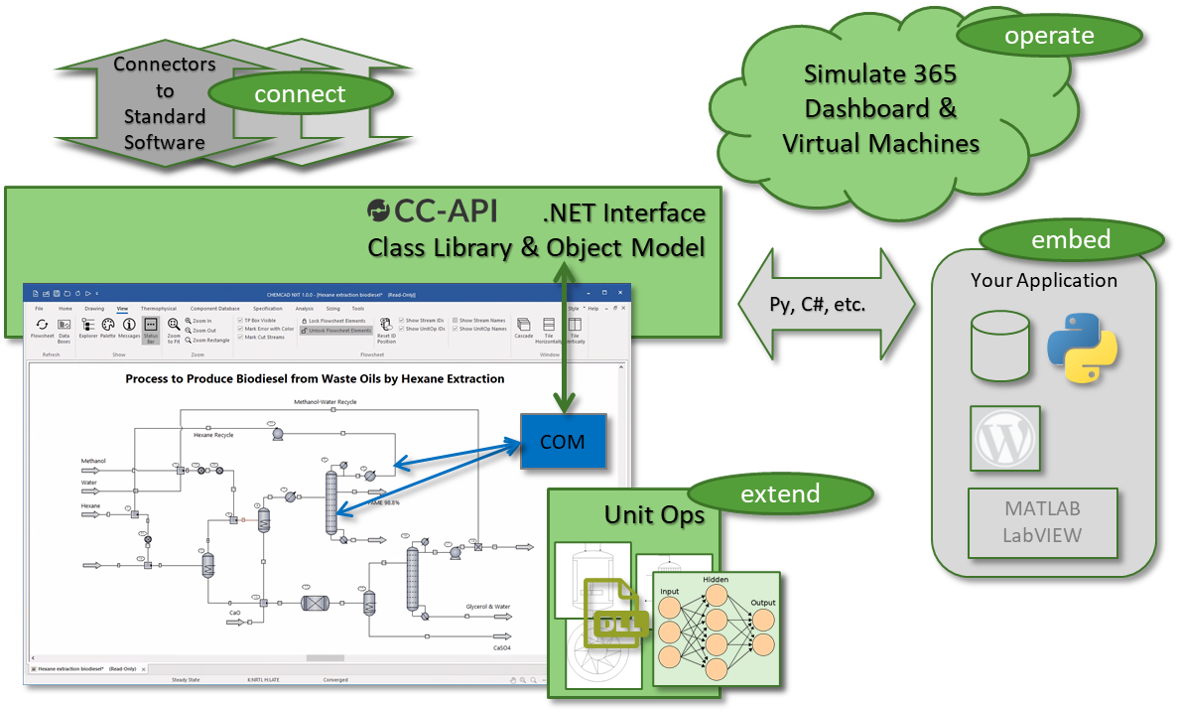

Connect

standard software to CHEMCAD

This way, another application can use CHEMCAD's thermodynamic calculations, i.e. access property data and thermodynamic models.

Embed

CHEMCAD in your application

Your application can be written in C# or it can be based on WordPress, MATLAB, or LabVIEW.

Extend

CHEMCAD with custom unit operations

Convert expertise and know-how into a model that is used in process design and optimization. Or get an innovative unit op from our shop.

Operate

CHEMCAD in the cloud

We have developed some applications that demonstrate the unique advantages of cloud computing.