PPBDesigner is a built-in column module in DWSIM Pro, the commercial sibling of the open-source process simulator DWSIM.

PPBDesigner in DWSIM Pro is accessible online with a personal login on any device. No download and installation is required.

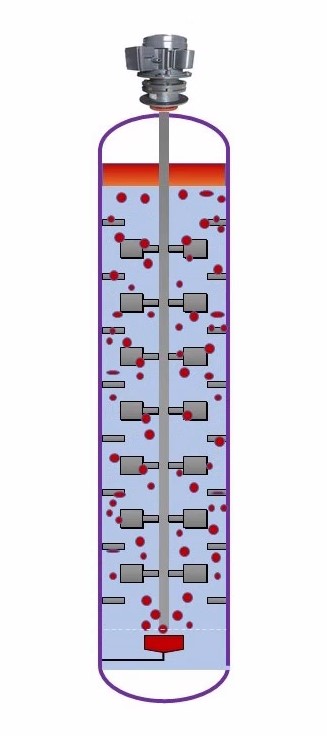

PPBDesigner is a software for modeling and simulation of discrete flow systems, such as liquid-liquid extraction columns (LLEC) with an application of detailed population balances.

It uses modern population balance solvers to discretize the internal particle coordinates, while the built-in space-time solvers are utilized to discretize the temporal-spatial domain.

Its LLEC modules (agitated and non-agitated columns) examine the effect of dispersed phase inlet and the direction of mass transfer on the column performance.

The particulate population balance framework considers the realistic character of the systems where particle motion is mainly governed by buoyancy and drag forces. The effect of turbulence, breakage, coalescence, growth, and solute transfer is built-in during the modeling process.

PPBDesigner takes these phenomena into account to bridge the gap between ideal LLEC modules and the real column performance.

It is a tool for both academia and industry practitioners to discover the different aspects of the phenomena considered in equipment design and performance.

You reduce the time invested in the early stage of development to confirm whether the unit operation is convenient for your process and whether it meets your performance requirement.

You get a realistic description of the coupled hydrodynamics and mass transfer phenomena in particulate processes.

You reduce costs associated with preliminary laboratory tests by eliminating the use of pilot plants and experiments.

PPBDesigner is a built-in column module in DWSIM Pro, the commercial sibling of the open-source process simulator DWSIM.

PPBDesigner in DWSIM Pro is accessible online with a personal login on any device. No download and installation is required.

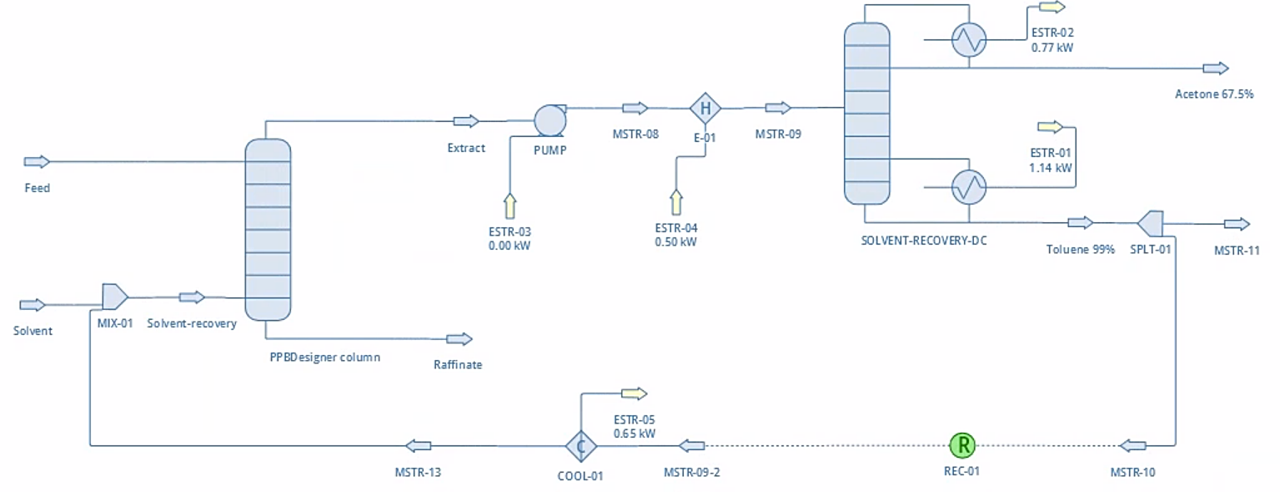

You can simulate a stand-alone column module or you can integrate PPBDesigner with other flowsheet modules for a complete chemical process flow diagram simulation.

It accesses simulator features such as thermodynamic property packages, sensitivity, and optimization tools.

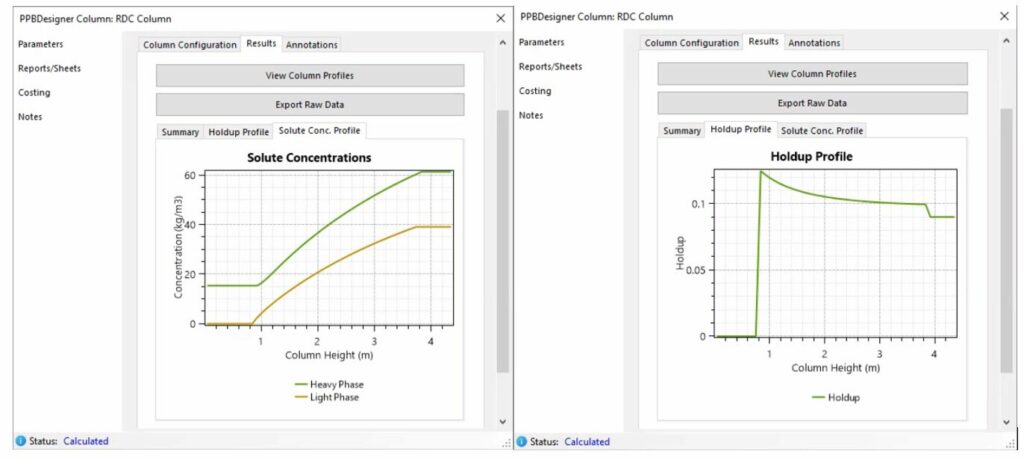

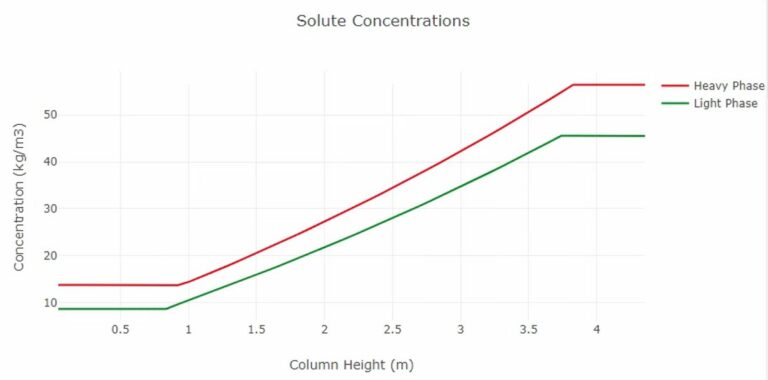

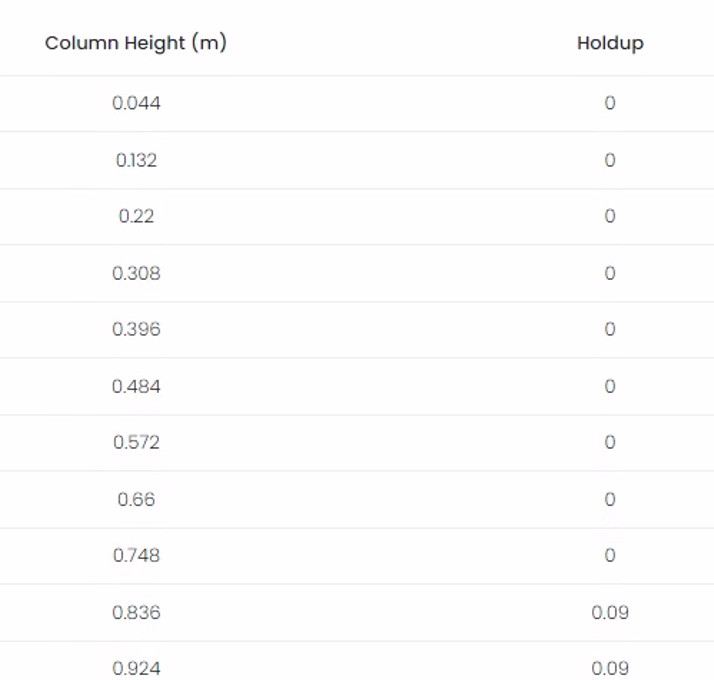

Graphical visualization of the results, such as solute concentration, hold-up profile and Droplet Size Distribution (DSD), are generated automatically within the simulator.

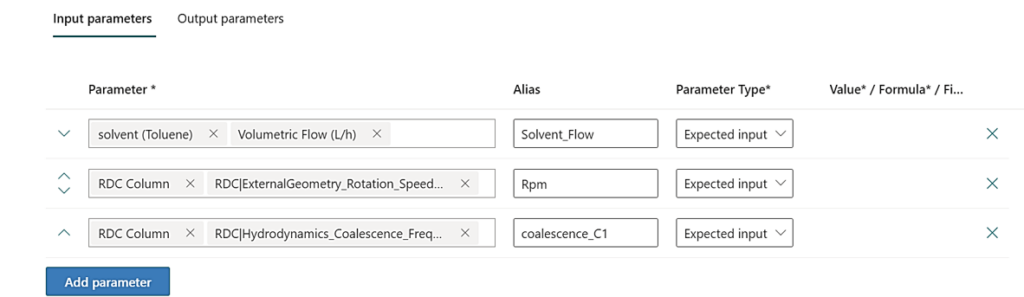

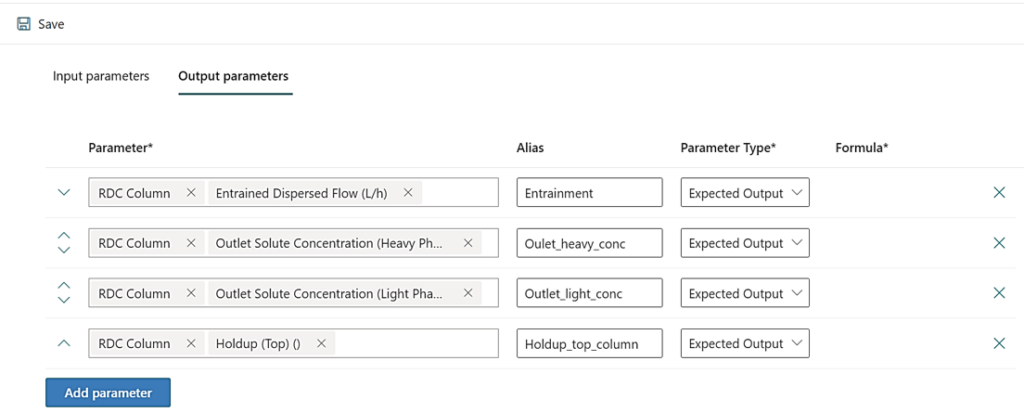

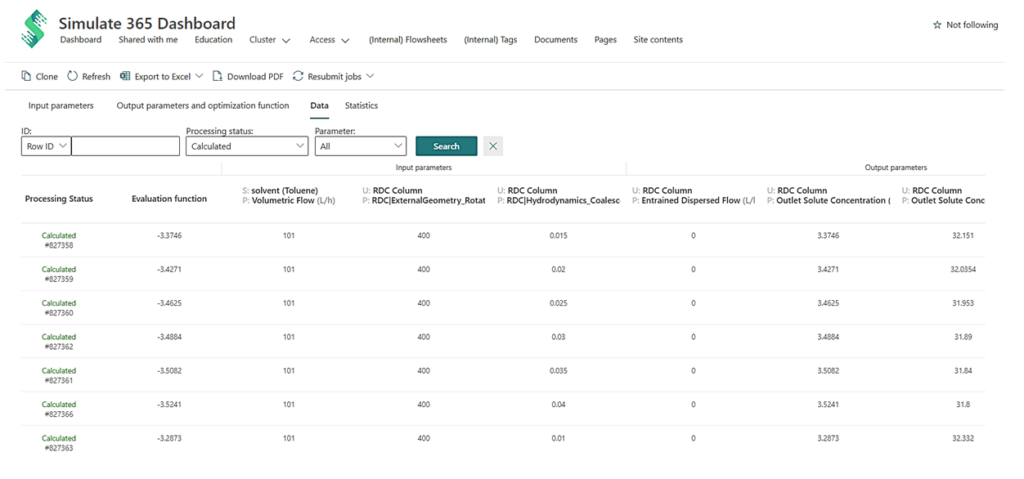

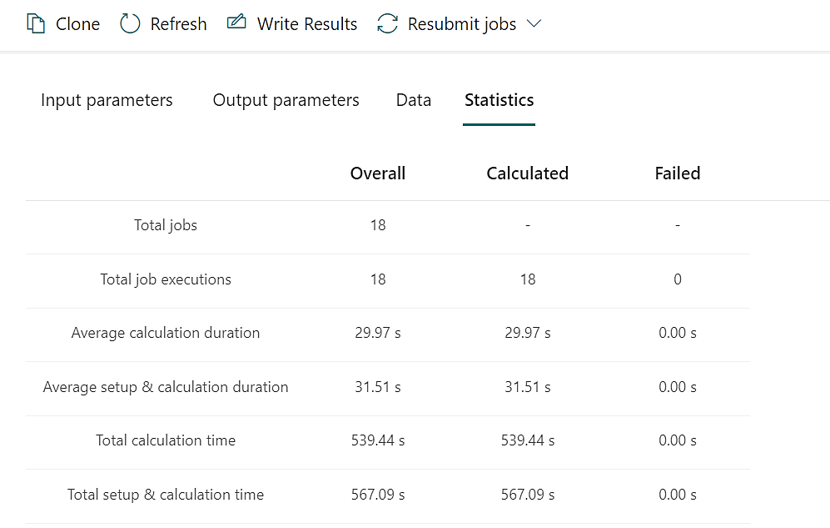

Multivariate Sensitivity Study (MSS) enables the investigation of the effect of multiple input parameters on the simulation results. It is an application hosted on Simulate 365 DASHBOARD that enables the creation of sensitivity analysis and optimization scenarios for PPBDesigner column.

You simulate lab-scale or mini-plant unit and set up different scenarios with MSS focusing on sensitive parameters to meet the desired output requirements.

You adjust the model parameters to bring simulation results closed to the corresponding experimental data.

You solve an optimization problem in multi-dimensional space with various constrains and objectives faster.

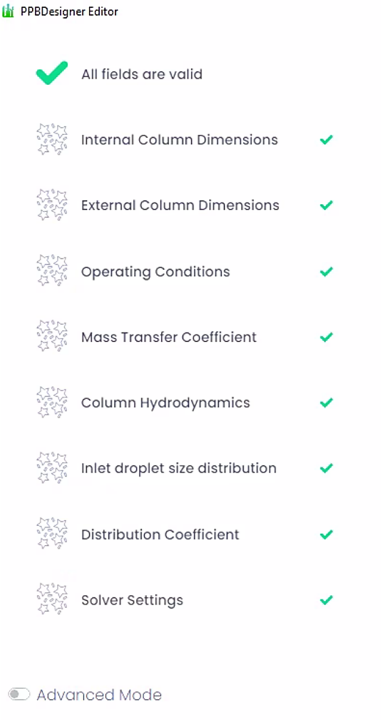

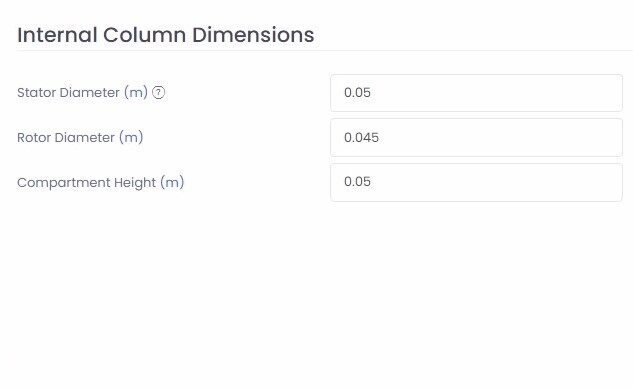

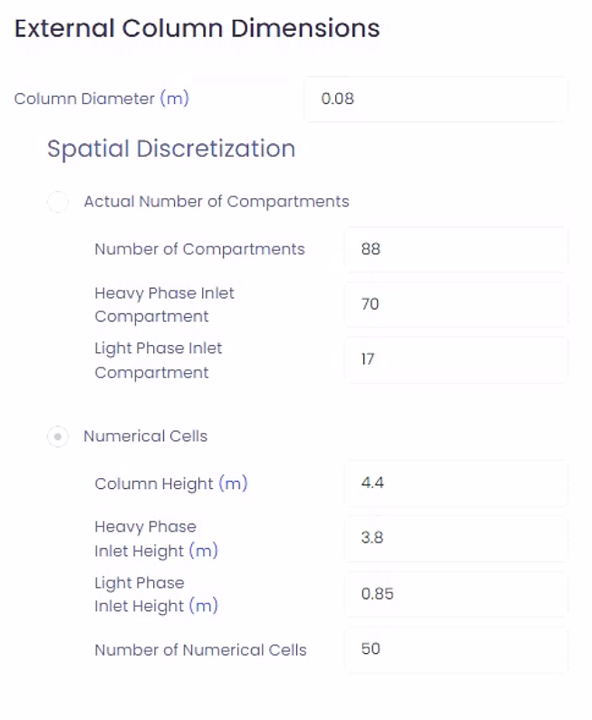

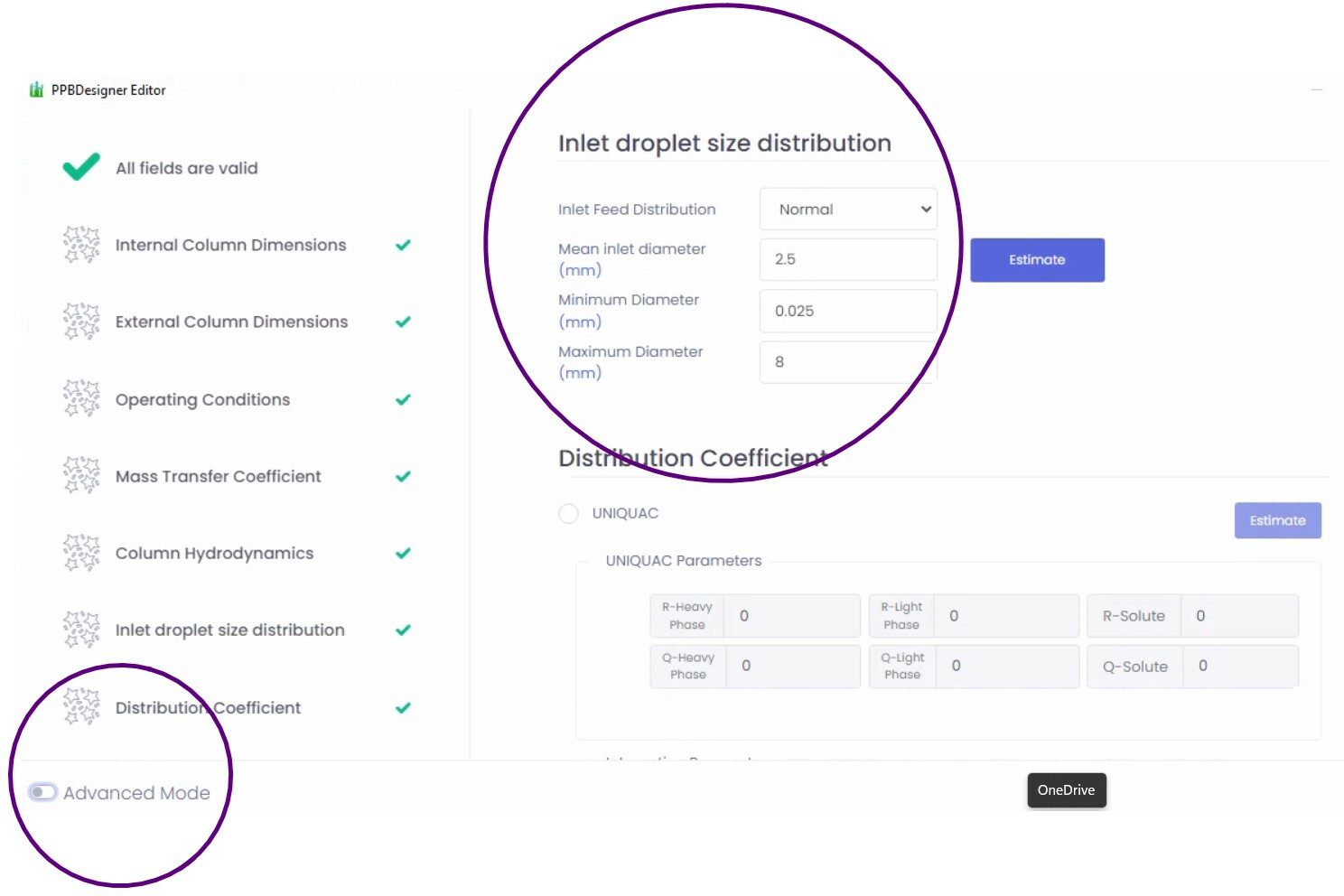

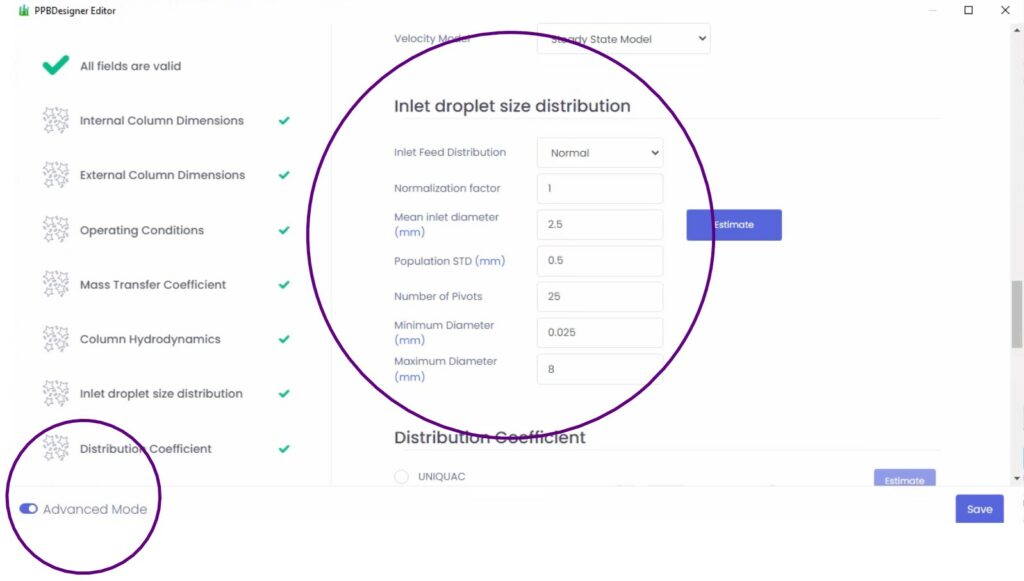

You define the column input parameters and select subpopulation balance models using the PPBDesigner Editor.

An automatic background check is performed to verify if all required user input is provided.

You start the simulation.

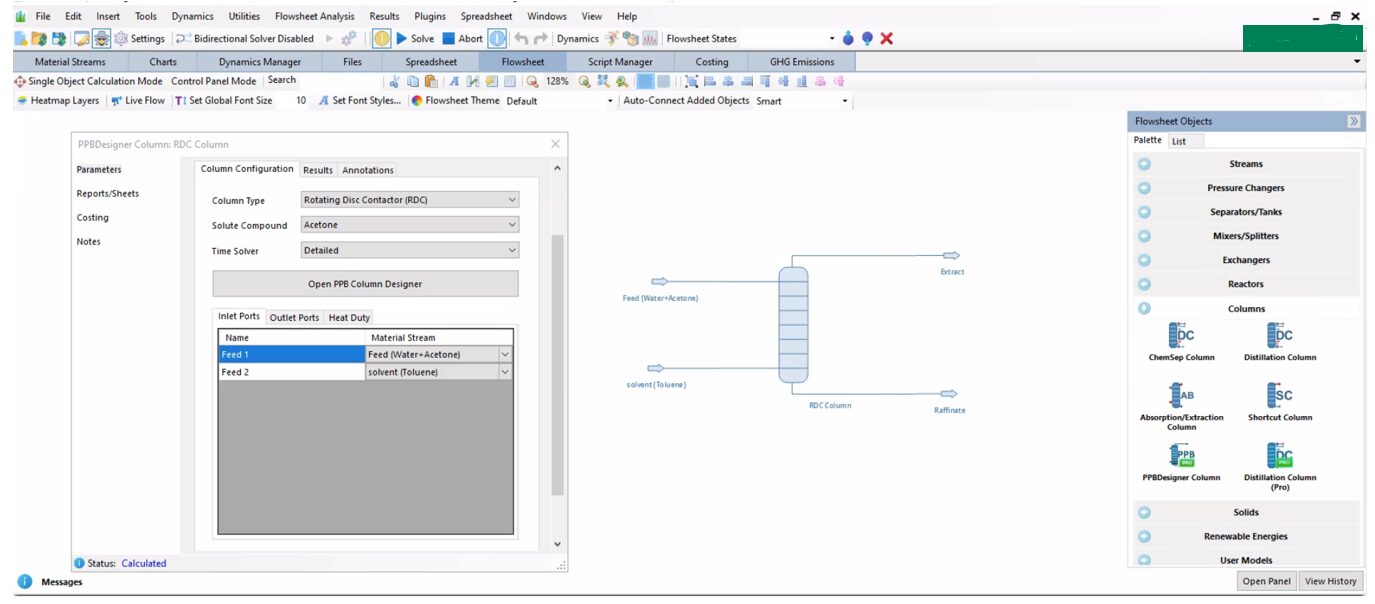

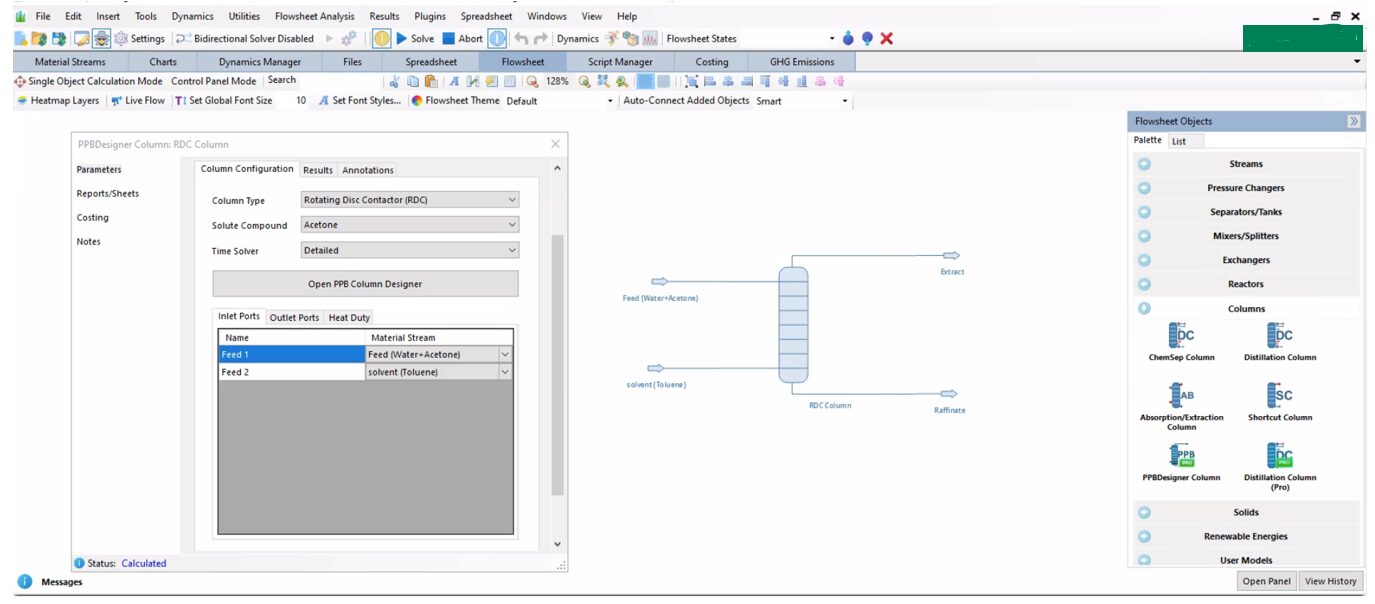

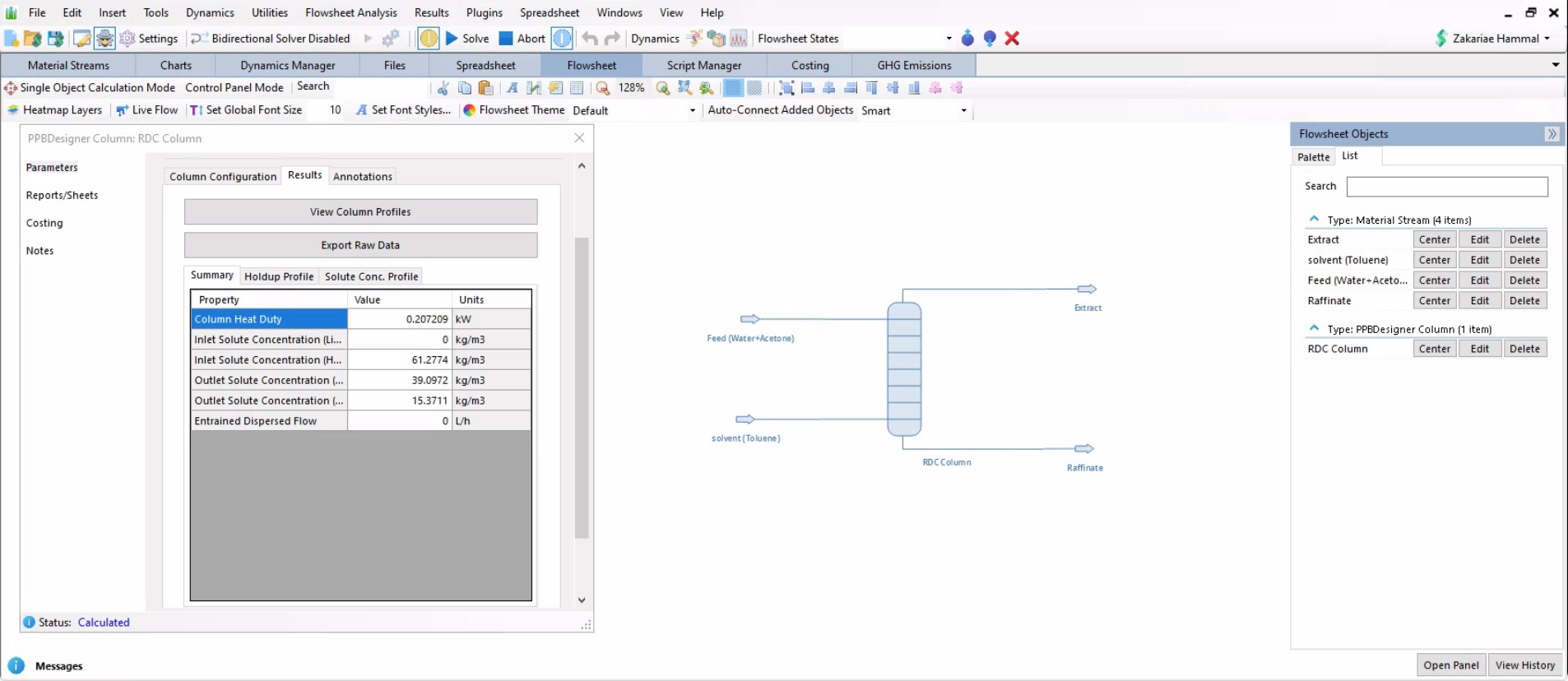

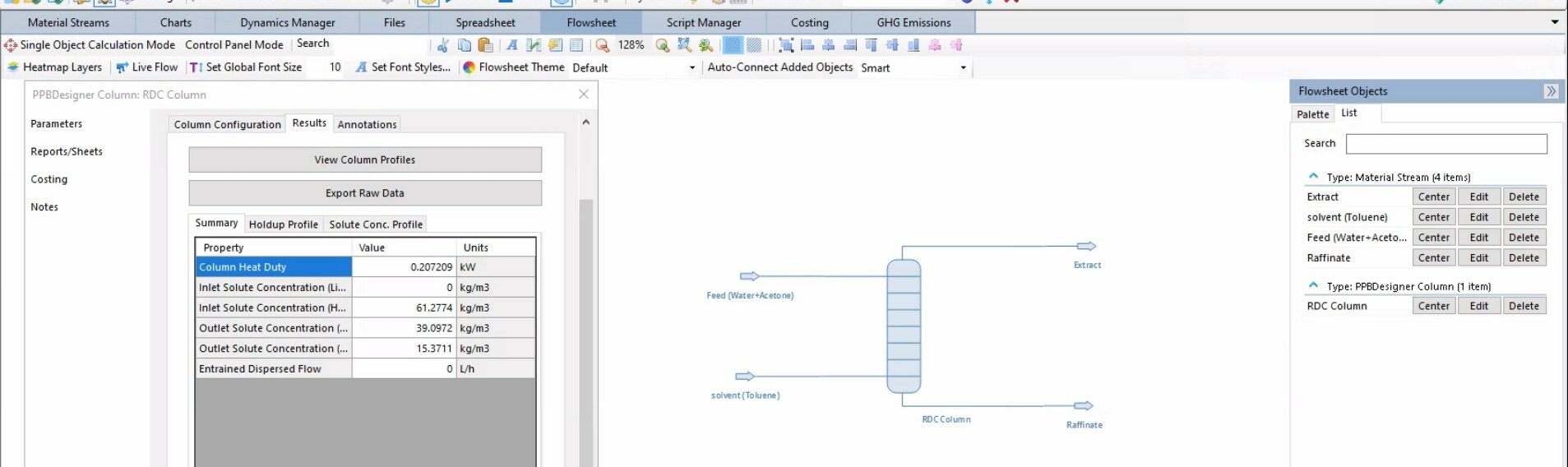

Simulation of a plant Rotating Disc Column (RDC) for extracting Acetone (Solute) from Water (aqueous phase) to Toluene (Organic phase).

Simulation of a plant Rotating Disc Column (RDC) for extracting Acetone (Solute) from Water (aqueous phase) to Toluene (Organic phase).

You can choose between standard and advanced modes for column design.

You can view the results in the simulation file.

You can access graphical and numerical displays of the simulation data and results in the PPBDesigner Editor.

Due to the 1D CFD space solvers and the efficient and advanced population balance methods used, PPBDesigner excels in terms of computer memory usage and computational time compared to 2D and 3D CFD software (order of minutes versus order of weeks and months). The simulation results are found close to those of 2D and 3D CFD simulations.

The simulation results include the PPBDesigner learning algorithm. The column hydrodynamics is learnt in the first step and the column performance is validated in the prediction. The predicted simulation results are comparable with the experimental data published in the literature.

With sufficient phenomena details embedded into the PPBDesigner, its capability for scaling up liquid-liquid extraction columns is remarkable and reliable.

Prof. Dr. Menwer Attarakih is a professor of Computer-aided Chemical Process Engineering and Industrial Mathematics and is currently the director of Accreditation & Quality Assurance Centre at and former Vice Dean for Quality Affairs & Accreditation/School of Engineering/University of Jordan.

As a guest professor at the Institute of Thermal Process Engineering, he spent regular research visits at the Institute of Process Engineering/University of Kaiserslautern/ Germany and Fraunhofer Institute for Industrial and Mathematical Economics during the summer of 2005 to the present.

He published more than 120 peer-reviewed papers and book chapters in well-known and reputable international Journals and participated in more than 50 peer-reviewed symposia and conferences.

He was honoured with the selection as a Testimonial in the Postgraduate & Doctoral Education by the International School for Graduate Studies (ISGS) at the University of Kaiserslautern/ Germany in 2008.

He was named and honoured as one of the top 10 percent of peer reviewers in Chemical Engineering in 2016 on Publons, where he is verified reviewer for the Chemical Engineering Science Journal, Chemical Engineering & Processing: Process Intensification Journal, Nuclear Engineering Journal, Journal of Computational Physics, Computers & Chemical Engineering Journal, Journal of Cleaner Production, the Chemical Engineering Research and Design Journals, and many more.

He is the Inventor of LLECMOD and PPBLab software for modelling and design of liquid-liquid extraction columns and SQMOM (US Patent 20100106467) as a discrete population balance framework to model discrete flow systems.

He invented and developed OPOSPM as a reduced population balance model which is used in the OPENFOAM Computational Fluid Dynamics (CFD) used by the open-source CFD toolkit OpenFOAM and is included in the release of OpenFOAM as multiphaseEulerFoam. Version 2.2.1. OPOSPM is used by Chemical Sciences and Engineering Division, Argonne National Laboratory, Argonne, IL 60439, USA to model centrifugal extractors to extract spent nuclear fuels.

He invented NQMOM a stable and reduced population balance solver which is implemented in the meshfree computational fluid dynamics software (FPM) of Fraunhofer Institute for Industrial and Mathematical Economics (ITWM)/Kaiserslautern/Germany. According to Reuters 2020, ITWM is ranked second worldwide as the top institution in scientific research and the number of inventions. (https://www.itwm.fraunhofer.de/en.html).

He developed CDA: A Conservative Discretization Method for discrete modelling and solution of Population Balances.

Developer of the Differential Maximum Entropy Method for solving Integral Population Balances.

Developer of the CQMOM, which recently solved the Moment Problem in Population Balances.

Worked on projects in modeling, troubleshooting, debottlenecking, design and operation with many leading international oil and petrochemical companies which include:

EDL Company in Leiptzeg/ Germany (http://www.edl.poerner.de/en.html).

SULZER Company/ Germany (http://www.sulzer.com/en/).

BASF/ Germany (http://www.basf.com/group/corporate/en/).

NOVARTIS/ Switzerland (http://www.novartis.com/).

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It is mandatory to procure user consent prior to running these cookies on your website.