Multivariate Sensitivity Study

to know your process

What is Multivariate Sensitivity Study?

Multivariate Sensitivity Study examines multiple input and output relationships and reveals their effects on process results.

It identifies parameters with a critical impact on the operating areas of the process. It allows for testing the alternative constraints and objectives.

For fast calculation, a Multivariate Sensitivity Study is calculated on a cluster of CHEMCAD / DWSIM instances.

It is for every engineer who wants to visualize the process behavior, get valuable insights for optimized operations, and improve energy and production efficiencies.

You can get the Multivariate Sensitivity Study here.

Why use the Multivariate Sensitivity Study?

Apply constraints with filters

You discover parameter dependencies and dimension reductions using big data analytics

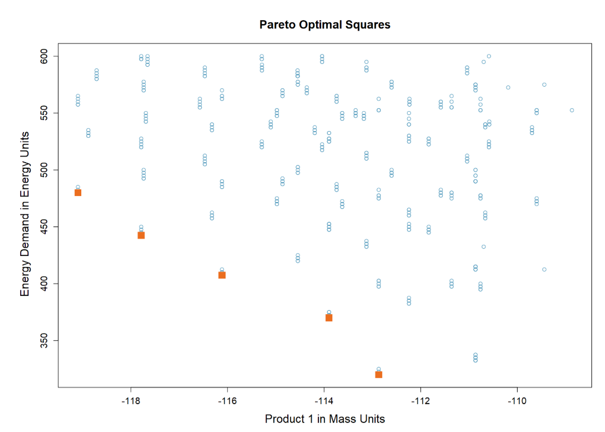

Find pareto-optimal solutions

You visualize solution spaces and pareto fronts for multi-objective optimization problems

Multivariate Sensitivity Study (MSS) is an application hosted on Dashboard, our simulation platform developed for process engineers working with flowsheets.

How sensitive is your process to parameter changes?

Learn more from our use cases

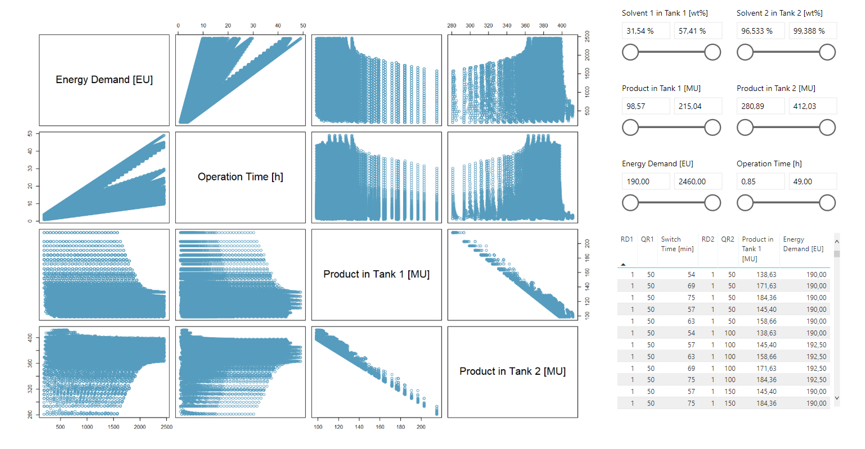

Case 1- Optimization of a Batch Distillation for Solvent Recovery

- Minimize energy demand

- Minimize operation time

- Maximize product yield

- Product concentration as a constraint

- Five design variables

- Equidistant grid (per variable)

- 78.125 flowsheet calculated (mass transfer batch column simulation)

Increased the solvent recovery efficiency

- 74% energy saving

- 4.5 h reduction in operation time

- 7% increase in product yield

- Infeasible design specifications cause convergence problems

- Due to product accumulation, product specifications must be given indirectly as design specifications

- The correlation of design and state variables are not obvious

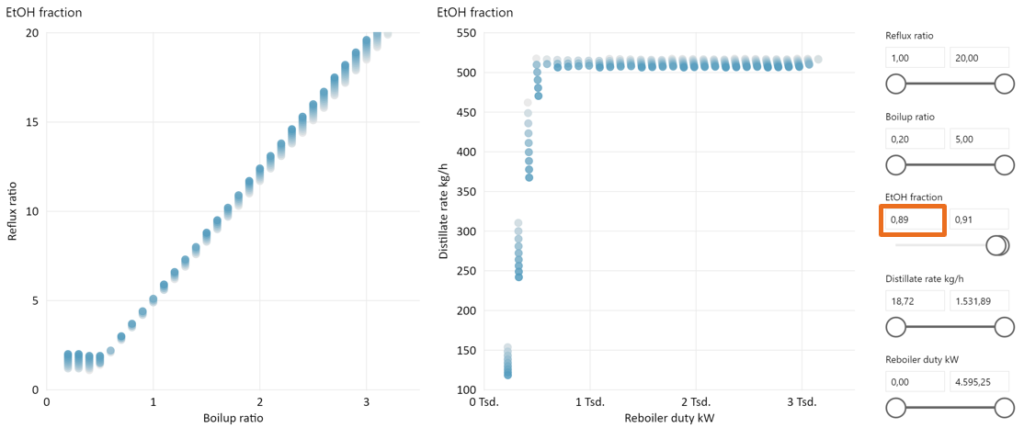

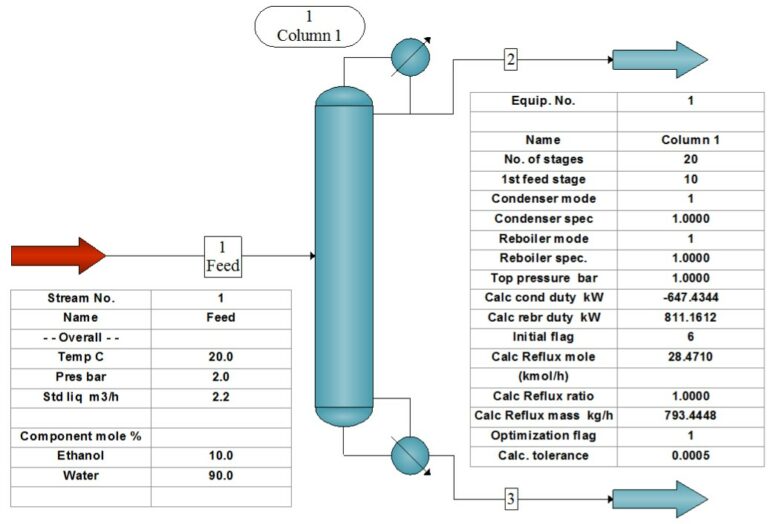

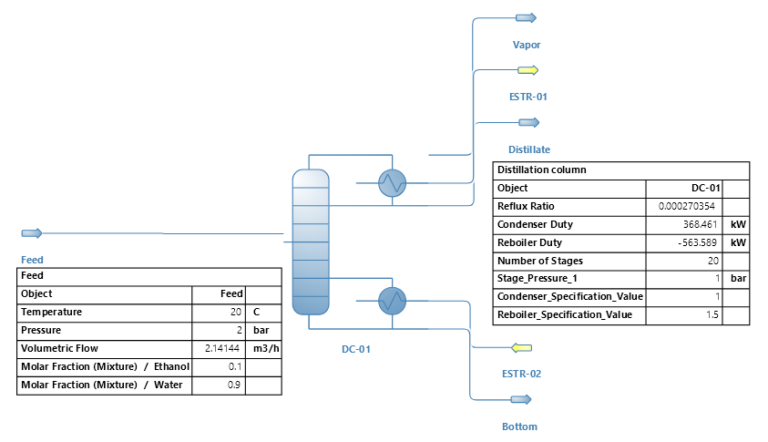

Case 2- Distillation of an Ethanol-Water Mixture (see video)

- Maximize product yield

- Minimize energy demand

- Product concentration as a constraint

- Two design variables

- Equidistant grid (per variable)

- 9.550 flowsheet calculated (SCDS)

Understand the correlations between variables

Flowsheet (CHEMCAD)

Flowsheet (DWSIM)

Interactive Data Explorer

Use the sliders on the report below to apply limitations! Observe the relationship between variables.

- EtOH fraction

- Distillate rate

- Reboiler duty